3D Printing of Salt as a Template for Magnesium with Structured Porosity

Publications

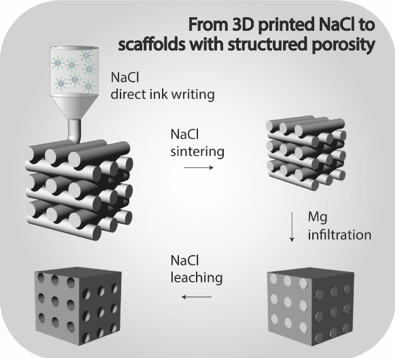

In a recent Adv. Mater. publication, researchers at the Laboratory of Metal Physics and Technology (LMPT) and Complex Materials have documented the creation of ordered porous Mg scaffolds via 3D NaCl printing (and sintering), Mg melt infiltration, and subsequent salt removal by leaching. These set the premise for a unique combination of tunable mechanical properties and the potential of being deployed as biodegradable implant, as the scaffold can be tuned to predictably biodegrade in the human body.

The introduction of porosity can effectively tune materials properties because such procedure generates a high surface area and a spatially variable density. In a recent Adv. Mater. publication, researchers at LMPT and Complex Materials have developed an ordered Mg scaffold that is of great interest in a wide range of applications such as catalysis, lightweight structural materials and biomedical implants. This was achieved via the generation of an ordered 3D printed NaCl template; subsequent sintering; infiltration of the template with Mg; and salt removal by leaching.

The authors rheologically engineered a printable paste via tuning the surfactant and liquid-phase composition, and made sure that all components revealed biological safety standards for deployment in medical applications. They developed a NaCl paste with 2.5 wt.% AOT and used paraffin oil to disperse the modified NaCl particles. The paste’s shape retention was designed to be such high that printed struts maintained their circular shape even through sintering. With the Mg-infiltration working very well, the authors were able to fabricate metal scaffolds with directional porosity, where the good surface wetting of the Mg melt on the NaCl template made possible even precise transcription of micrometer-sized features, and subsequent re-shaping by drilling, turning and grinding. The ordered Mg-scaffolds offer great advantages in 3D-cell culture and tissue engineering by supporting guided cell growth, or in lightweight structural applications via the introduction of anisotropic mechanical properties with corresponding weight reduction.

- 3D Printing of Salt as a Template for Magnesium with Structured Porosity, N. Kleger, M. Cihova, K. Masania, A. R. Studart, J. F. Löffler, Adv. Mater. 1903783 (2019) 1-10. external pageDOI:10.1002/adma.201903783call_made

- Laboratory of Metal Physics and Technology

- Complex Materials